- Joined

- Sep 26, 2013

- Messages

- 408

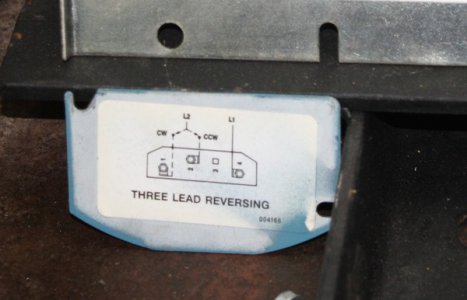

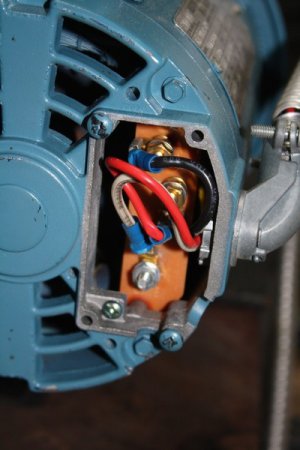

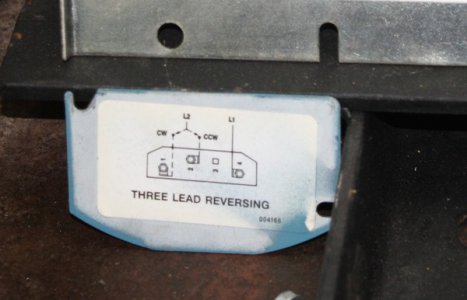

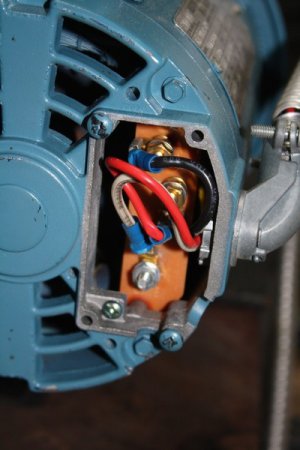

Got this from the scrap yard, need some info on the motor like how do I hook up a manual switch for it, what type of switch, etc. Unless it was on a fairly long run I don't get why it used #10 wire for only 4 amps. Why is there no ground wire, was it relying on the flex conduit for the ground? . All made in USA; had a short section of 1/4" stainless cable on the drum. Pretty nice unit; if possible I want to make some sort of shop lift with it.

thanks, Brian

Electra-Gear History

Founded in 1946, Electra-Gear is a leading supplier of industrial duty aluminum gear reducers, offering unsurpassed advantages of weight reduction and surface durability to alternative cast iron models and cost savings to stainless steel. Electra-Gear was acquired in 1989 by Regal-Beloit Corporation, a worldwide manufacturer of mechanical and electrical motion control products. Today, Electra-Gear products are manufactured in Union Grove, Wisconsin by Grove Gear and sold through LEESON Electric sales offices throughout the world.

Electra-Gear products are built for industrial use and are already used in most markets, including: boat lifts, car washes, door and gate openers, material handling, packaging machinery, medical specialties, power generation, exercise and recreation equipment. All Electra products have numerous features making them easy to install in new applications or as replacements to many popular brands. Electra-Gear is also well known for custom-designed or modified worm and helical gear products to meet customers’ strictest application requirements.

Combine an aluminum Electra-Gear reducer with a LEESON or Lincoln stainless steel motor to instantly create a performance-matched and paint-free Gear+Motor to meet the standards of most severe environments with single source responsibility and quick availability.

Download the EL Series catalog here.

thanks, Brian

Electra-Gear History

Founded in 1946, Electra-Gear is a leading supplier of industrial duty aluminum gear reducers, offering unsurpassed advantages of weight reduction and surface durability to alternative cast iron models and cost savings to stainless steel. Electra-Gear was acquired in 1989 by Regal-Beloit Corporation, a worldwide manufacturer of mechanical and electrical motion control products. Today, Electra-Gear products are manufactured in Union Grove, Wisconsin by Grove Gear and sold through LEESON Electric sales offices throughout the world.

Electra-Gear products are built for industrial use and are already used in most markets, including: boat lifts, car washes, door and gate openers, material handling, packaging machinery, medical specialties, power generation, exercise and recreation equipment. All Electra products have numerous features making them easy to install in new applications or as replacements to many popular brands. Electra-Gear is also well known for custom-designed or modified worm and helical gear products to meet customers’ strictest application requirements.

Combine an aluminum Electra-Gear reducer with a LEESON or Lincoln stainless steel motor to instantly create a performance-matched and paint-free Gear+Motor to meet the standards of most severe environments with single source responsibility and quick availability.

Download the EL Series catalog here.

Last edited: