Necroposting this because this morning I had a thought of making a 29º angle block to use up against the compound. Using that and a dial indicator I would dial in the compound. However, since I already have 30º angle blocks I'm wondering about this.....

Using a 3" long 30º angle block affixed to the vertical side of the compound; using a DI to get the 30º vertex end away about 0.0227" by rotating compound counter-clockwise. Using a sine bar I figure 3" length piece at 30º is 1.50" height. A 29.5º setting is 1.4773" (rounded) height. So 1.50" - 1.4773"= 0.0227".

Would this get me a 29.5º compound setting? Am I off my rocker and laying on the ground?

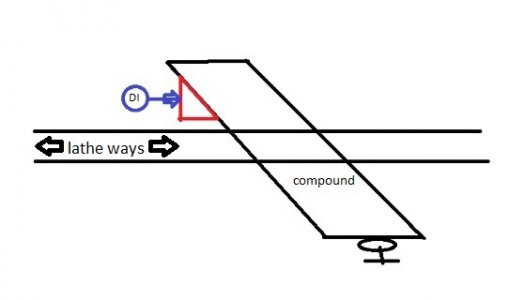

Forgive the crude drawing but wanted to show you what I'm talking about:

View attachment 368494

To the OP, sorry for hijacking your thread here.