Okay I got this motor wiring figured out finally, here's the info to maybe save others time and head scratching. I will delete my above posts since they were all wrong lol. This was a great opportunity to learn more about motors and how to wire them. So here we go...

Supply Power 220vac e.g. there are two hot wires I'll call them Line 1 Hot and Line 2 Hot

Primary Run Winding - in the diagram below for wiring a 220v motor (for Forward direction) you see the primary run windings terminals 1,2,3,4. There are actually 2 windings hence 4 terminals so that was something new I learned. Line 1 Hot connects to terminal 1 and Line 2 Hot connects to terminal 4, simple.

Secondary Start Winding - again there are two windings hence 4 terminals 5,6,7,8. Terminals 5 and 8 are the ones that determine which direction the motor will turn forward/reverse. For forward rotation terminal 8 is connected to Line 1 Hot and terminal 5 is connected to the junction of 2,3 on the primary run winding (see diagram below). For reverse just the opposite terminal 5 is connected to Line 1 Hot and terminal 8 is connected to the junction of 2,3 on the primary winding. Again simple now that I see this diagram below.

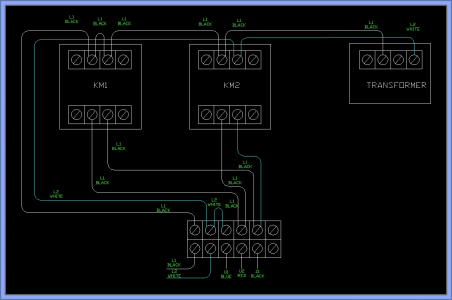

Switching Forward/Reverse - Jim is going to laugh...Friday I drove 2.5 hours to downtown Portland in rush hour traffic to buy 4 conductor power cord to wire this up...and I actually need 5 conductor cord (face palm). So some machines use a barrel switch for forward/reverse. My lathe uses relays and contactors. Both do pretty much the same thing, flip terminals 5 and 8 between Line 1 Hot or join them to the junction of terminals 2,3 on the primary winding.

This is the diagram for wiring the motor for Reverse, all they did was flip terminals 5 and 8.