- Joined

- Mar 25, 2013

- Messages

- 5,128

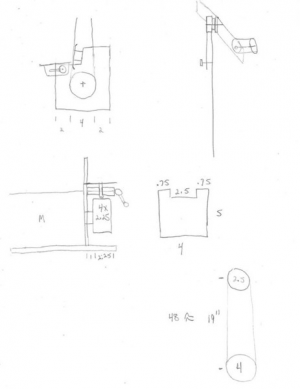

I started on my belt grinder!

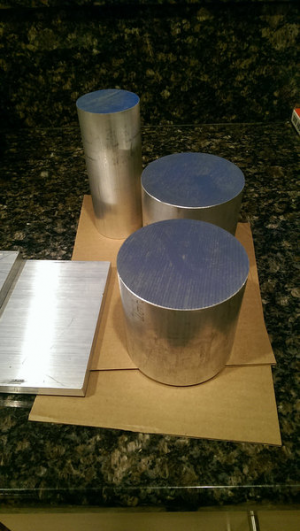

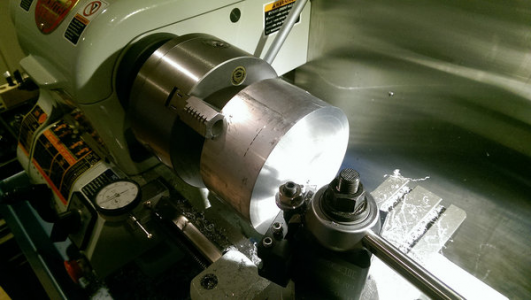

I built this motor from scratch from scrap bin parts. I think it looks OK, although the capacitors are a little big. (Yes I know it reminds you of your ex but please refrain from commenting.)

Specs are 3/4 HP @ 3450 RPM. Already blows 15 amp circuits.

It's a start.

Robert

I built this motor from scratch from scrap bin parts. I think it looks OK, although the capacitors are a little big. (Yes I know it reminds you of your ex but please refrain from commenting.)

Specs are 3/4 HP @ 3450 RPM. Already blows 15 amp circuits.

It's a start.

Robert

Last edited: