- Joined

- Apr 12, 2011

- Messages

- 3,472

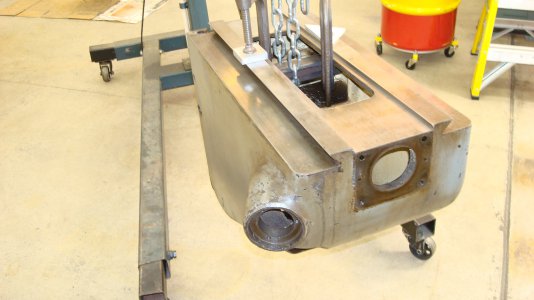

At the encouragement of others on this site I am going to expose my lack of knowledge and goofy ideas on the refurbishing of my 1958 Bridgeport series 1J. I am not completely green to machine tools but lack experience. I am very adept to tinkering with mechanical things. So here is my story. I got lucky last month and purchased my mill off of Craig's list. Probably over paid for it considering what I have learned since ($3500). I really like the fact it is single phase 110v. Once I got it home and off the trailer using my 2 post auto lift. I proceeded to move it into position by using several pieces of ¾ inch conduit under the base and just rolled it into position. I already knew the turret and ram were rusted solid to each other before the purchase. Here are the photos of day one.

View attachment 41821

View attachment 41820

View attachment 41822

View attachment 41819

View attachment 41818

View attachment 41821

View attachment 41820

View attachment 41822

View attachment 41819

View attachment 41818

Last edited by a moderator: