- Joined

- Feb 2, 2013

- Messages

- 3,625

One of the first operations i attempted was to start the drive motor.

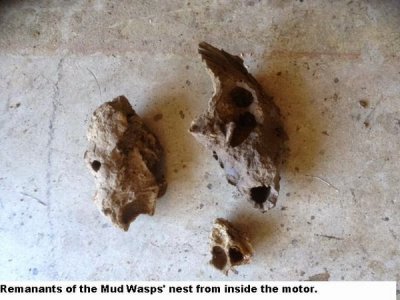

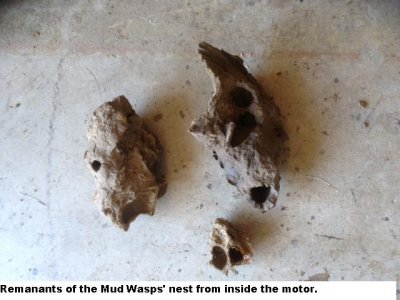

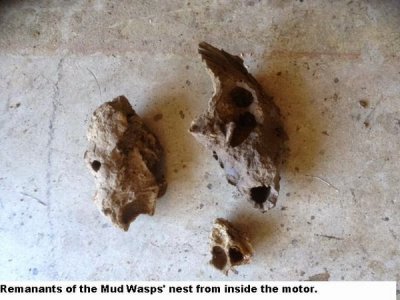

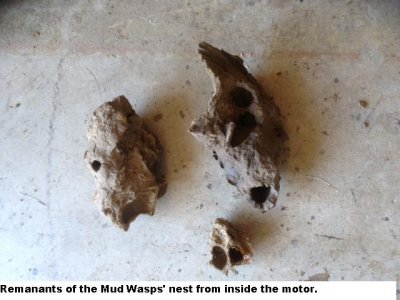

the motor didn't want to turn and sounded like rocks were inside the motor. on the bench i saw what appeared to be dirt clods inside the motor. i disassembled the motor and this fell out among other smaller pieces and dust.

I'll be sure to but heart back in as soon as i clean up the motor mounting.

thanks for looking, and supporting this build!

the motor didn't want to turn and sounded like rocks were inside the motor. on the bench i saw what appeared to be dirt clods inside the motor. i disassembled the motor and this fell out among other smaller pieces and dust.

I'll be sure to but heart back in as soon as i clean up the motor mounting.

thanks for looking, and supporting this build!

Last edited: