- Joined

- Sep 23, 2010

- Messages

- 619

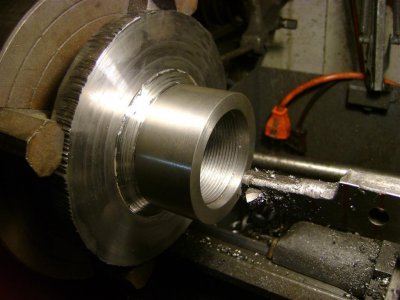

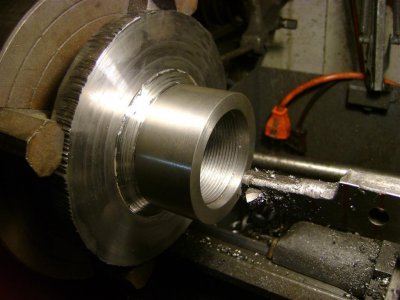

I have a 15" 1919 and a fellow at the PM forum has a 14 1/2" 40's lathe and needs a chuck plate made. So i am making a few of them since i will need a couple of them also. I bored some 3" HRS to 2.00 then mig welded it to a 6" 1/2" thick HRS plate. After an hour it was cool so i chucked it in my 8" 4 jaw and got it trued up. Then i bored it to 2.087 and cut the register 2 1/4" to match my spindle. Then came the threading with my trusty home made boring bar and cleaning up the backside edges. When the customer gets it he can face it to suit as well as cut the dia. I am also going to make another ER40 collet chuck body for my 15" spindle while i am cutting...Bob