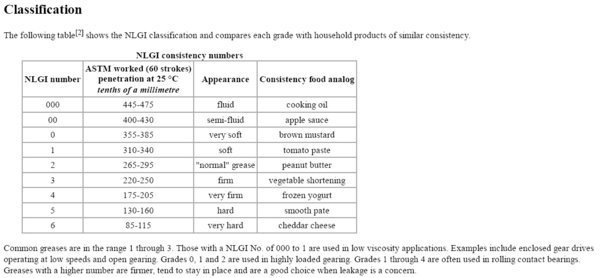

Wanted to check the viscosity rating of NLGI 1 grease, I got a laugh on how they describe the consistency. I commonly used NLGI 2 on mechanical joints, packing bearing races and on open gears. Works well and is very sticky/tacky, but you would want something thinner for these type of machine bearing surfaces as others have noted. Any good NLGI 1 grease should work well, I like the moly based but they can be messy in this application. A synthetic grease is less likely to separate out with heat/friction and stiffen when cold, so would be preferable.

Although my dad many years ago invented many lubricating products that incorporated PTFE, many of which I used, I find a good synthetic grease works equally well.

View attachment 189586