Guys does anyone know of a source for 150 viscosity oil?I really don't want to buy 2 different viscosity oil so I was thinking that maybe I could just get by with the 150 for both the headstock and apron. Tks again kroll

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

150 Viscosity Oil for the SB

- Thread starter Kroll

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

150 using which of the many standards for viscosity?Guys does anyone know of a source for 150 viscosity oil?I really don't want to buy 2 different viscosity oil so I was thinking that maybe I could just get by with the 150 for both the headstock and apron. Tks again kroll

- Joined

- May 4, 2014

- Messages

- 30

150 sounds like th e old ASTM grading system. ASTM 150 would equate to ISO 32. You can look around for #32 hydraulic oil which will work well for spindle oil. Shell sells Tellus 32. Many auto parts stores sell hydraulic jack oil which is usually 32. By the way 32 equates to viscosity only and falls into the 10 wt range.

I use 32 for both apron and headstock, it works well. Don't use it as way oil though.

I use 32 for both apron and headstock, it works well. Don't use it as way oil though.

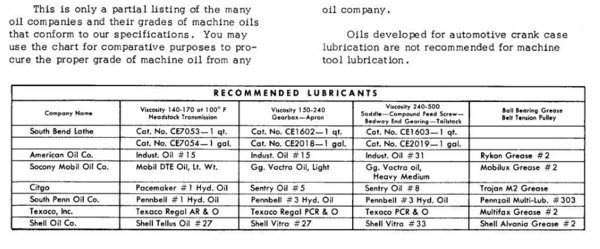

The chart you posted is for Saybolt 100 degree F . types oil, there are two systems one at 100 degrees F and the other if I remember correctly is at 300 degrees F.

Van Norman milling machines call for 300 Sec. at 100 degrees F. and that translates to DTE Heavy Medium.

You do not want to use 150 weight oil as measured today. I have a cross reference between the old systems and modern oil on one of my hard-drives. I'll see if I can locate it.

Mike

I just found this on the net, you want the ISO equivalent of the saybolt viscosity that your lathe calls for. Looks like 32 was right on the money.

https://bobistheoilguy.com/viscosity-charts/

Van Norman milling machines call for 300 Sec. at 100 degrees F. and that translates to DTE Heavy Medium.

You do not want to use 150 weight oil as measured today. I have a cross reference between the old systems and modern oil on one of my hard-drives. I'll see if I can locate it.

Mike

I just found this on the net, you want the ISO equivalent of the saybolt viscosity that your lathe calls for. Looks like 32 was right on the money.

https://bobistheoilguy.com/viscosity-charts/

Last edited:

- Joined

- May 4, 2014

- Messages

- 30

The chart you posted is for Saybolt 100 degree F . types oil, there are two systems one at 100 degrees F and the other if I remember correctly is at 300 degrees F.

Van Norman milling machines call for 300 Sec. at 100 degrees F. and that translates to DTE Heavy Medium.

You do not want to use 150 weight oil as measured today. I have a cross reference between the old systems and modern oil on one of my hard-drives. I'll see if I can locate it.

Mike

I just found this on the net, you want the ISO equivalent of the saybolt viscosity that your lathe calls for. Looks like 32 was right on the money.

https://bobistheoilguy.com/viscosity-charts/

When I was drafting my response to Kroll I wanted to suggest more than one brand. I was trying to think of the Mobil spec but couldn't, I've lost too much grey matter. I think the upper end of the SUS scale was 200 degrees. The target temp for optimal oil temperature in an automotive engine.

regards

- Joined

- Nov 14, 2014

- Messages

- 851

Kroll, I use GL-1 rated 90 weight straight mineral oil in all my machines. This has equivalent viscosity to 30 wt motor oil, but is formulated for older gear boxes and really any non-hypoid gear meshing systems -e.g. Lathe and mill headstocks, 1950's auto and farm transmissions, etc.

You can usually find GL-1 one gal Mineral oil jugs in most auto part stores. This rating standard is printed on the label of each jug. just look for "gear lube mineral oil" or similar. It has no additives that leach out yellow metals that may be present in the gears, bearings, or seals.

Also, GL 1 lube oils have larger, more random molecular size than modern, high pressure hypoid shaped transmission gears. This larger molecular size insures the lube oil adheres to the teeth and edges of the gears properly. Modern hypoid oils are so small and uniform molecularly, that they physically run off the edges of low pressure gearing during operation. Hence do not lubricate properly and cause excessive/premature wear. The hypoid additives also attack some older metals.

Glenn

You can usually find GL-1 one gal Mineral oil jugs in most auto part stores. This rating standard is printed on the label of each jug. just look for "gear lube mineral oil" or similar. It has no additives that leach out yellow metals that may be present in the gears, bearings, or seals.

Also, GL 1 lube oils have larger, more random molecular size than modern, high pressure hypoid shaped transmission gears. This larger molecular size insures the lube oil adheres to the teeth and edges of the gears properly. Modern hypoid oils are so small and uniform molecularly, that they physically run off the edges of low pressure gearing during operation. Hence do not lubricate properly and cause excessive/premature wear. The hypoid additives also attack some older metals.

Glenn

Glenn and Jim and anyone else with knowledge about small gear boxes with "yellow metal" gears.

Not to get too far off topic but is this GL-1 the lube that I should use in my small garden/lawn tractor trans and tiller gearbox? Both call for 90 weight gear oil and I know that they have brass/bronze in the gearboxes.

Mike

Not to get too far off topic but is this GL-1 the lube that I should use in my small garden/lawn tractor trans and tiller gearbox? Both call for 90 weight gear oil and I know that they have brass/bronze in the gearboxes.

Mike

- Joined

- May 4, 2014

- Messages

- 30

Kroll, I use GL-1 rated 90 weight straight mineral oil in all my machines. This has equivalent viscosity to 30 wt motor oil, but is formulated for older gear boxes and really any non-hypoid gear meshing systems -e.g. Lathe and mill headstocks, 1950's auto and farm transmissions, etc.

You can usually find GL-1 one gal Mineral oil jugs in most auto part stores. This rating standard is printed on the label of each jug. just look for "gear lube mineral oil" or similar. It has no additives that leach out yellow metals that may be present in the gears, bearings, or seals.

Also, GL 1 lube oils have larger, more random molecular size than modern, high pressure hypoid shaped transmission gears. This larger molecular size insures the lube oil adheres to the teeth and edges of the gears properly. Modern hypoid oils are so small and uniform molecularly, that they physically run off the edges of low pressure gearing during operation. Hence do not lubricate properly and cause excessive/premature wear. The hypoid additives also attack some older metals.

Glenn

Glenn, if you look at reeltor's post and follow it to BobThe Oil Guy's chart you will see 90wt equates to 40 to 50wt plus. I dont know where you're located but you might see some flow problems at low temps with 90wt. Mobil DTE heavy mediun and Shell tellus 33 have excellent lubrication properties and much improved flow properties at low temps. Plus it's probably cheaper.

I use chain oil as way oil because it sticks to the ways, some people call it bar oil. It's made for chain saws.