After some recent photo rummaging, I realized I never posted my improved carriage lock pics, so here you go.

The stock mechanism was always kind of a vague & iffy. Sometime it would tighten sometimes not. Pushing on the nut & tightening simultaneously seemed to work best. But if the nut ever became loose more than a full turn, the entire clamp & post would extend out of the carriage hole & you had to fiddle it back into position. Even when locked, the carriage never really felt too secure. And sometimes it would spin & partially grab just traversing the carriage.

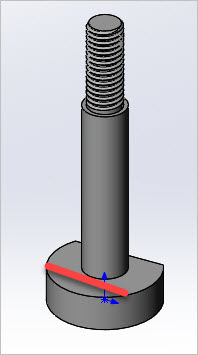

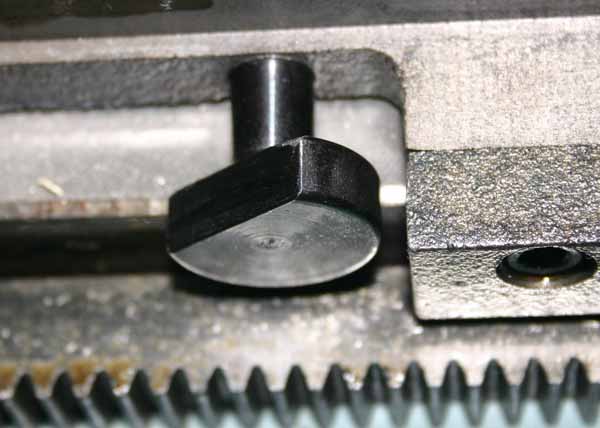

I had to remove the carriage for another reason so this provided opportunity for a closer look. Hopefully the pics tell the story. The design is not the best. The foot only provides minimal contact area to the casting bed. I think the milled flat on the foot segment is somehow intended to be contained by the front of carriage housing, but it just didn’t match up in my case for whatever reason. The good part is the hole is drilled nice & close to the bed lip.

The stock mechanism was always kind of a vague & iffy. Sometime it would tighten sometimes not. Pushing on the nut & tightening simultaneously seemed to work best. But if the nut ever became loose more than a full turn, the entire clamp & post would extend out of the carriage hole & you had to fiddle it back into position. Even when locked, the carriage never really felt too secure. And sometimes it would spin & partially grab just traversing the carriage.

I had to remove the carriage for another reason so this provided opportunity for a closer look. Hopefully the pics tell the story. The design is not the best. The foot only provides minimal contact area to the casting bed. I think the milled flat on the foot segment is somehow intended to be contained by the front of carriage housing, but it just didn’t match up in my case for whatever reason. The good part is the hole is drilled nice & close to the bed lip.