- Joined

- Dec 26, 2016

- Messages

- 2,015

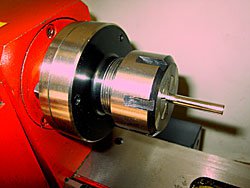

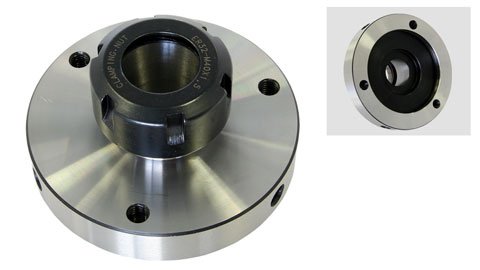

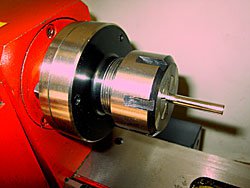

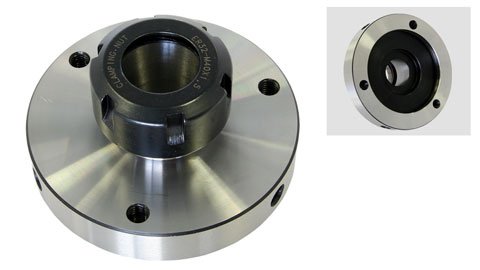

What's your opinion on using this collet chuck on a lathe for holding smaller diameter workpiece? is it more suitable for smaller lathes ? there has been a few occasions that I hoped for a better / firmer or more reliable chuck that the 3 jaw chuck/mini lathe.

I'm aware the MT3 collets could be used in the same way with a shopmade drawbar or an ER32/MT3 collet holder could achieve the same thing (I used ER32 just as an example) but correct me if I'm wrong, the last two options will limit the length of the workpiece that can be inserted in the collet when compared to the 100 mm chuck I was inquiring about which allows 25/32" stock through the headstock of the lathe. so longer stock will be alright.

I'm not convinced I will use it often enough at this stage in the hobby but the few times I tried to hold a long piece of 1/4" aluminum rod in my 3 jaw chuck (w/o using dead/rotary center for knurling or threading ), I was constantly worried if I tighten the chuck hard enough , or will the workpiece get loose/slip if I add any more pressure.those were the times I wished I had a better work holding tool.

I'm aware the MT3 collets could be used in the same way with a shopmade drawbar or an ER32/MT3 collet holder could achieve the same thing (I used ER32 just as an example) but correct me if I'm wrong, the last two options will limit the length of the workpiece that can be inserted in the collet when compared to the 100 mm chuck I was inquiring about which allows 25/32" stock through the headstock of the lathe. so longer stock will be alright.

I'm not convinced I will use it often enough at this stage in the hobby but the few times I tried to hold a long piece of 1/4" aluminum rod in my 3 jaw chuck (w/o using dead/rotary center for knurling or threading ), I was constantly worried if I tighten the chuck hard enough , or will the workpiece get loose/slip if I add any more pressure.those were the times I wished I had a better work holding tool.