- Joined

- Jul 7, 2012

- Messages

- 144

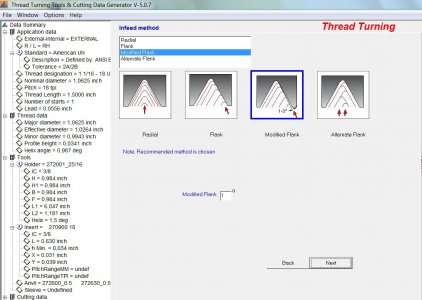

running a calculator it gives me the preferred method is 1-3°

if I understand it right I place the compound at 1° (nearly strait in)

and do all the feeding with the compound (nearly the same as feeding in the cross slide)

I prefere(lazy me ) the radial methode and do all the feeding with the cross slide( I got only 2 DRO's )

I wonder if there is mutch of a diff in finish

if I understand it right I place the compound at 1° (nearly strait in)

and do all the feeding with the compound (nearly the same as feeding in the cross slide)

I prefere(lazy me ) the radial methode and do all the feeding with the cross slide( I got only 2 DRO's )

I wonder if there is mutch of a diff in finish