- Joined

- Jul 13, 2014

- Messages

- 1,051

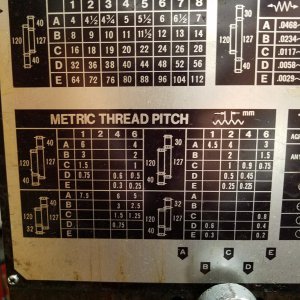

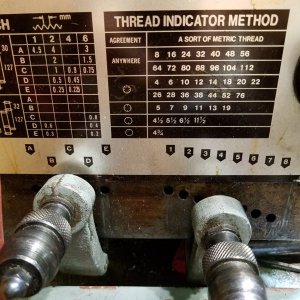

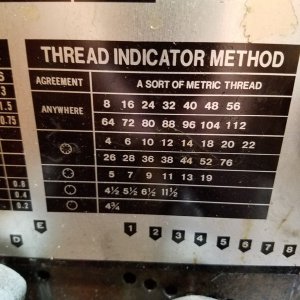

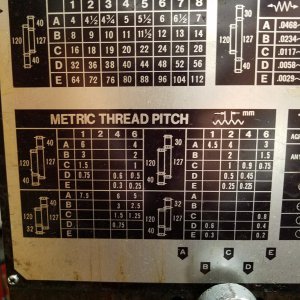

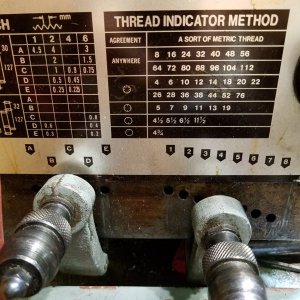

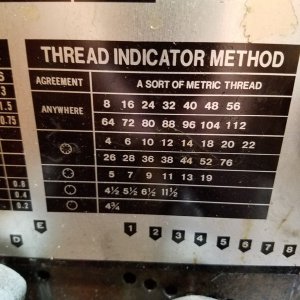

On my 1236 lathe I have threaded 16, 18, 24, and 28. Yesterday was the first time I tried 20. Since I have threaded on the same "C" gear of the L side of the QCGB, I just grabbed the "4" gear on the R side for the 20 TPI. When I got close to the point I needed to check the thread with the barrel extension, it will thread about 3 turns and stop. I grabbed the thread gauge and it not not match the 20 TPI

Is the gear in "4" position not right, the "C" position on the L side must be correct since I have threaded 16, 18, 24, and 28 with no problem.

Here is another kicker, my 1024 has the data plate for threading and the side gears are the same, but I was able to thread 20 TPI with it with no problem.

What's going on?

Is the gear in "4" position not right, the "C" position on the L side must be correct since I have threaded 16, 18, 24, and 28 with no problem.

Here is another kicker, my 1024 has the data plate for threading and the side gears are the same, but I was able to thread 20 TPI with it with no problem.

What's going on?