- Joined

- Sep 14, 2017

- Messages

- 52

Earlier in 2017 I decided to upgrade my Harbor Freight (Central Machinery) 7 x 10 mini-lathe as I was seeing many online videos which were advising improvements for this lathe. One very rewarding upgrade was one I ran across when I visited the littlemachineshop.com website which offers parts and upgrades for many machines. The most important upgrade was to eliminate the problem some of these lathes have with the graduations on the cross slide and compound slide control wheels. Mine was not usable. For example, a radial cut of .1mm reading the cross slide dial gave me an actual result of .15 mm. A radial cut of .004" on the dial gave me an actual cut of .0045. I decided that if I was to use these dials there had to be a change. First and most important, the exact model of the machine must be known to determine if the upgrade kit available is compatible to the lathe. Anytime I purchased from littlemachineshop.com I could see on the website parts description where a compatibility list for that part was published. This makes life easier to say the least.

ABOUT THE 20 TPI KIT, "2383 Feed Screw Parts, 20 TPI, Mini Lathe" from Littlemachineshop.com.

This is a great kit and Littlemachine Shop was very good at helping me with problems. It seems that all of these particular lathes are not exact to specs. and these parts may or may not be exact to each lathe and my lathe must be one of them. After the kit was installed, the compound slide screw retainer was causing binding and they replaced it free of charge free shipping which solved the problem. I had guessed that the cause was the retainer they sent in the kit was untrue and I must have been correct because the replacement worked fine. The next problem was probably due to differences in lathe specs. The cross slide had a .007" slack with the kit installed. My lathe originally had a .003" slack which was annoying enough. Littlemachineshop was willing to change parts but I took this opportunity to solve the slack problem COMPLETELY by making a .007" shim. The cross slide now has practically zero slack. My email to them explained the success of this effort:

""If you recall, I had mentioned that there was a .007" unacceptable slack in the cross slide control after I installed the 20 TPI kit. You offered to send a new retainer but I wasn't sure if the slack was caused by the retainer or the feed screw or both so I declined the offer. I said I was going to try to shim the cross slide feed. I ordered some .007" steel shim stock from another supplier and I made a shim to fit on the cross slide feed screw which would go over the threaded end and take out the slack between the shoulder on the feed screw and the cross slide body. I had to thin the shim to about .0068" with a whetstone and the end result was perfection. There is zero slack and the wheel turns smoothly as well, no binding, no slack. Of course I still do not know whether it is the feed screw or the retainer that caused the slack I can't say but it is one or the other.

The reason I wanted to shim is because I hoped for a near zero slack which is even better than what the manufacturer engineered into this lathe. With my shim this zero slack was attained with great satisfaction. It is easier to shim out a .007" slack than a .003" which is usually what these lathes have as built so to me the slack was a fortunate invitation to improve the performance of the cross slide. Thin shims of .002" or .003" would tend to tear easily or fold inside cutting shears.

I drilled the hole in the shim tightly clamped and sandwiched between two pieces of wood. This way the hole is clean and the drill doesn't bite. I then tin snipped to attain close to the outside dia. and ground it round on the grinder holding it with pliers and finished the edge with a whetstone by hand. With experimentation I fine tuned the thickness from .007" to @ .0068" to attain a smooth and unbinding crank control of the cross slide. The end product result was a round shim with an O.D. of .587" with a hole .366". The shim has improved my lathe beyond the original engineering and has eliminated a lot of problems with chattering, vibration and over bite of the tool bit especially when using a longer holder-bit tip distance and when using parting (cutoff) bits.

Telling you all this so if someone needs help you can tell them how I improved the lathe. Also it might be a good idea to manufacture and sell shim kits with various thicknesses that can be used singly or stacked to take the factory slack out of the Harbor Freight / General Machinery mini-lathes. ""

Although the upgrade was not without problems, as described above, I highly recommend this upgrade for those lathes which were shipped with the inaccurate dial increments. I can actually use the dials for measuring with good precision and it was a breath of fresh air over the old dials. Also I managed to improve, even eliminate the excess slack in the XY feed screws. As a (very) amateur machinist I was able to accomplish great satisfaction with this upgrade, and most people should be able to install it.

Wayne

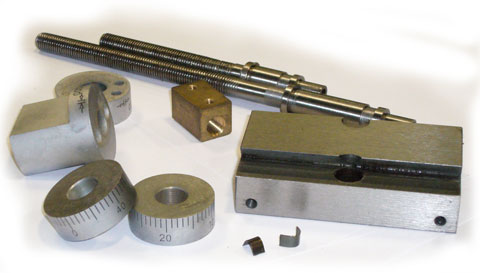

ABOVE PIC... THE KIT

ABOVE PIC... THE CROSS SLIDE FEED SCREW IN THE KIT. THE HOMEMADE DOUGHNUT SHIM IS FITTED OVER THE SCREW END AND RESTS AGAINST THE SHOULDER TO TAKE UP SLACK BETWEEN THE SHOULDER AND THE CROSS SLIDE FACE.

ABOUT THE 20 TPI KIT, "2383 Feed Screw Parts, 20 TPI, Mini Lathe" from Littlemachineshop.com.

This is a great kit and Littlemachine Shop was very good at helping me with problems. It seems that all of these particular lathes are not exact to specs. and these parts may or may not be exact to each lathe and my lathe must be one of them. After the kit was installed, the compound slide screw retainer was causing binding and they replaced it free of charge free shipping which solved the problem. I had guessed that the cause was the retainer they sent in the kit was untrue and I must have been correct because the replacement worked fine. The next problem was probably due to differences in lathe specs. The cross slide had a .007" slack with the kit installed. My lathe originally had a .003" slack which was annoying enough. Littlemachineshop was willing to change parts but I took this opportunity to solve the slack problem COMPLETELY by making a .007" shim. The cross slide now has practically zero slack. My email to them explained the success of this effort:

""If you recall, I had mentioned that there was a .007" unacceptable slack in the cross slide control after I installed the 20 TPI kit. You offered to send a new retainer but I wasn't sure if the slack was caused by the retainer or the feed screw or both so I declined the offer. I said I was going to try to shim the cross slide feed. I ordered some .007" steel shim stock from another supplier and I made a shim to fit on the cross slide feed screw which would go over the threaded end and take out the slack between the shoulder on the feed screw and the cross slide body. I had to thin the shim to about .0068" with a whetstone and the end result was perfection. There is zero slack and the wheel turns smoothly as well, no binding, no slack. Of course I still do not know whether it is the feed screw or the retainer that caused the slack I can't say but it is one or the other.

The reason I wanted to shim is because I hoped for a near zero slack which is even better than what the manufacturer engineered into this lathe. With my shim this zero slack was attained with great satisfaction. It is easier to shim out a .007" slack than a .003" which is usually what these lathes have as built so to me the slack was a fortunate invitation to improve the performance of the cross slide. Thin shims of .002" or .003" would tend to tear easily or fold inside cutting shears.

I drilled the hole in the shim tightly clamped and sandwiched between two pieces of wood. This way the hole is clean and the drill doesn't bite. I then tin snipped to attain close to the outside dia. and ground it round on the grinder holding it with pliers and finished the edge with a whetstone by hand. With experimentation I fine tuned the thickness from .007" to @ .0068" to attain a smooth and unbinding crank control of the cross slide. The end product result was a round shim with an O.D. of .587" with a hole .366". The shim has improved my lathe beyond the original engineering and has eliminated a lot of problems with chattering, vibration and over bite of the tool bit especially when using a longer holder-bit tip distance and when using parting (cutoff) bits.

Telling you all this so if someone needs help you can tell them how I improved the lathe. Also it might be a good idea to manufacture and sell shim kits with various thicknesses that can be used singly or stacked to take the factory slack out of the Harbor Freight / General Machinery mini-lathes. ""

Although the upgrade was not without problems, as described above, I highly recommend this upgrade for those lathes which were shipped with the inaccurate dial increments. I can actually use the dials for measuring with good precision and it was a breath of fresh air over the old dials. Also I managed to improve, even eliminate the excess slack in the XY feed screws. As a (very) amateur machinist I was able to accomplish great satisfaction with this upgrade, and most people should be able to install it.

Wayne

ABOVE PIC... THE KIT

ABOVE PIC... THE CROSS SLIDE FEED SCREW IN THE KIT. THE HOMEMADE DOUGHNUT SHIM IS FITTED OVER THE SCREW END AND RESTS AGAINST THE SHOULDER TO TAKE UP SLACK BETWEEN THE SHOULDER AND THE CROSS SLIDE FACE.

Last edited: