- Joined

- Apr 9, 2017

- Messages

- 42

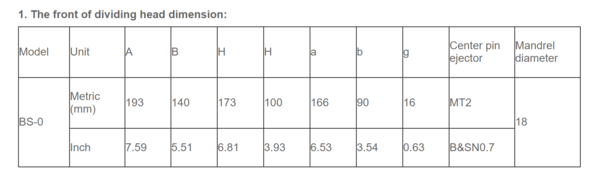

OK, I picked up a BS-0 (5" dividing head)... oy, that's heavy. After taking an aspirin for my back, I see on the box that they also offer a 4" version... BS-00? They don't say. But I wish I could have found that, would be better on my X2 mini mill.

Mine comes with a 3-jaw chuck, which is not shown in the instruction booklet. Also not shown is how to remove the chuck... anyone with experience have a clue????

See the pic... it's attached with M8 Allens, which can't be accessed through the plain index plate. And they're smooth and hard, can't get a grip with pliers. It's like some sort of 3D jigsaw puzzle...

And the back-plate appears to thread onto a central spud, but I don't see a way to break it loose without pounding on things that shouldn't be pounded on.

Mine comes with a 3-jaw chuck, which is not shown in the instruction booklet. Also not shown is how to remove the chuck... anyone with experience have a clue????

See the pic... it's attached with M8 Allens, which can't be accessed through the plain index plate. And they're smooth and hard, can't get a grip with pliers. It's like some sort of 3D jigsaw puzzle...

And the back-plate appears to thread onto a central spud, but I don't see a way to break it loose without pounding on things that shouldn't be pounded on.

Last edited: