- Joined

- Jul 13, 2014

- Messages

- 1,051

Thanks, Ken. I got a quote from Brian Miller for screw and nut. He claims the backlash on his set up, assuming all is well with the rest is around 0.003 to 0.006.

The first thing I did was fix the nut at the end of the screw by the taper attachment. The thrust washer was bottoming out on shaft shoulder, but not against the housing. I could literally push the screw back and forth. I machined a pocket in the washer so it goes over the shoulder and bear agains the housing. Polished the side of the washer. The backlash went from about a full rev down to 0.080.

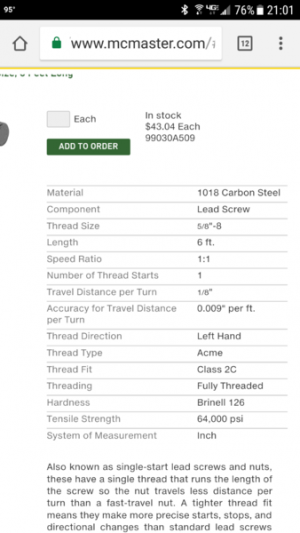

I might take you up on the offer. Would the ACME rods from McMaster good enough?

The first thing I did was fix the nut at the end of the screw by the taper attachment. The thrust washer was bottoming out on shaft shoulder, but not against the housing. I could literally push the screw back and forth. I machined a pocket in the washer so it goes over the shoulder and bear agains the housing. Polished the side of the washer. The backlash went from about a full rev down to 0.080.

I might take you up on the offer. Would the ACME rods from McMaster good enough?