A

Alan H.

Forum Guest

Register Today

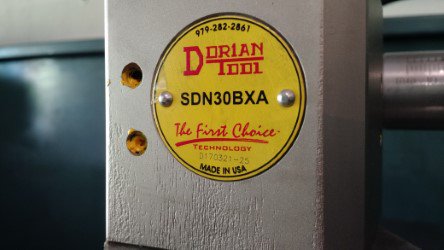

I am aware that my experience with Dorian is not unique. I know of others having similar bad customer service experiences with Dorian. So poor customer service appears to be symptomatic of the company's culture.

I have had two significant contacts with them regarding quality issues and found both times that their customer service was abysmal. This thread is one of the two.

I am not trying to be arrogant, but I am old enough and have enough scars on me to recognize a cultural issue in a company when I see it. Combined with my personal experience with them and that of others that I know and trust, I am personally convinced that Dorian has a cultural fault based on beliefs that must run from the corner office. I have already spent enough time and my hard earned money on them. I am not willing to try to fix a problem with them that is most likely being promulgated by the boss.

I pushed forward and fixed the holder. The additional time I was willing to spend on this is here to help others. I wanted to share my specific experience so others could find and evaluate it before they buy the Dorian "grab bag". While I could find this information in my research, it was not in one place and/or succinct enough to keep me from stepping into the tar pit.

I have had two significant contacts with them regarding quality issues and found both times that their customer service was abysmal. This thread is one of the two.

I am not trying to be arrogant, but I am old enough and have enough scars on me to recognize a cultural issue in a company when I see it. Combined with my personal experience with them and that of others that I know and trust, I am personally convinced that Dorian has a cultural fault based on beliefs that must run from the corner office. I have already spent enough time and my hard earned money on them. I am not willing to try to fix a problem with them that is most likely being promulgated by the boss.

I pushed forward and fixed the holder. The additional time I was willing to spend on this is here to help others. I wanted to share my specific experience so others could find and evaluate it before they buy the Dorian "grab bag". While I could find this information in my research, it was not in one place and/or succinct enough to keep me from stepping into the tar pit.