-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2017 POTD Thread Archive

- Thread starter jpfabricator

- Start date

- Joined

- Dec 12, 2012

- Messages

- 109

Last night I really stepped up my lathe game by commissioning the new QCTP and using indexable carbide cutters. The first project on the new setup was a set of Swingarm Spools for the race bike. Wow what a difference using the QCTP and carbide inserts!

B

British Steel

Forum Guest

Register Today

Just taking a break from today's - yesterday was get everything out of the garage, move shelving etc. around and move the Birthday present to self into place with Bro-I-L's machine skates (1962 universal mill, *may* be a Dormac?), then it rained (well, this IS England) so today I'm drying stuff off, deciding what's junk and what isn't, trying to organise it all and squeeze it back in :/

Dave H. (the other one)

Dave H. (the other one)

- Joined

- Mar 19, 2017

- Messages

- 308

The thickness is one inch the diameter is 39-1/4 inches those legs are 4"x 4"x 1/2" thickThat there looks like one really rugged round table. Whats the the diameter and thickness of the top?

This is one heavy table

- Joined

- Jan 9, 2016

- Messages

- 120

I made some mods to the mini lathe and mill over the last few weeks. I converted to tapered brass gibs on the mini lathe. Based on the design by Rick Kruger ( see the attached PDF). It's no longer a hassle to adjust the front gib. Very much smoother carriage travel and no loose slop in the carriage. Really helps in parting operations too. Before the mod I had to disassemble the carriage and apron to get to the gib adjustment screws. Now no need to disassemble anything. I used 360 brass for the gibs and 11L17 for the L brackets. The gibs and L brackets are milled at a 1°

Roy

Nice!

Did you mic the ways and do any filing (accurizing?) before taking on this modification?

- Joined

- Aug 23, 2014

- Messages

- 932

Nice!

Did you mic the ways and do any filing (accurizing?) before taking on this modification?

I mic'd and measured everything. The ways are pretty good and there are barely detectable tight spots that just don't cause any problem. No accurizing was needed. This is one modification that really makes a difference. These little machines are all hand fitted so it is best to check everything. Some of the guys who hand fit them are obviously half blind and use a yardstick for measurements. I have the original cross slide that I replaced with the extended travel kit so I just used it to get measurements and then after machining I made any small correction as needed. There were not many corrections needed, mainly shaving the width of the gibs for a couple of thousandths clearance on the front and rear. The good part is nothing is modified so the original system can be reinstalled easily.

Roy

- Joined

- Jun 12, 2014

- Messages

- 4,806

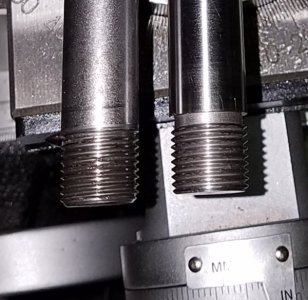

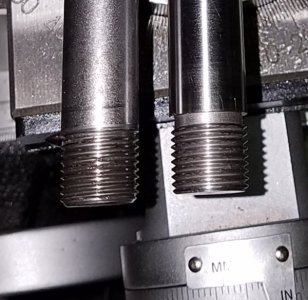

Have not been happy with the hold down stud that came with my Dorian tool-post because the threading was a bit rough, the top hold down nut had a bit of play and the shaft was very loose between it and the QCTP body. Started out with some 3/4" O2 drill rod, that I turned down to the proper size and cut down the ends for the 5/8-18 thread on either end. Turned the threads on the lathe, but I use an adjustable thread die to set the final size/fitment of the thread so it is a snug fit to the nut. The stock post on the left has pretty poorly cut threads at bot ends. The new post works nicely.

- Joined

- Feb 17, 2013

- Messages

- 4,406

Durn ... yet another problem with Dorian quality

I especially like how you have a shoulder above the threads that go into the T-nut. Helps prevent the stud from bottoming out on the slide and possibly cracking the T slot with upward pressure.

I especially like how you have a shoulder above the threads that go into the T-nut. Helps prevent the stud from bottoming out on the slide and possibly cracking the T slot with upward pressure.