- Joined

- Feb 7, 2013

- Messages

- 2,485

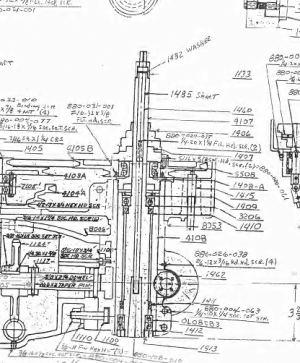

This morning's project was to make the tool to remove the Brown and Sharpe taper on my Gorton 9J mill.

The first project was to make a 12TPI left handed nut. That was interesting as there was no way to

test fit without multiple set ups. After that was accomplished, I fabricated a washer of sorts for the

draw bar to push up on and dislodge the taper. The washer is held on with 4 1/4 inch Allen Head cap

screws. Not knowing what the tool was supposed to look like made this a bit challenging along with

the fact that left hand threads in a blind hole didn't seem easy to do.

This tool just threads on by hand and when the draw bar is loosened, it pushes down on the taper

and dislodges it. I thought it worth my whiile to make this so one doesn't have to beat on the draw bar

and bearings.

Here's a couple photos:

View media item 96429View media item 96430

My guess is that you use this tool and remove it when done using it...

The first project was to make a 12TPI left handed nut. That was interesting as there was no way to

test fit without multiple set ups. After that was accomplished, I fabricated a washer of sorts for the

draw bar to push up on and dislodge the taper. The washer is held on with 4 1/4 inch Allen Head cap

screws. Not knowing what the tool was supposed to look like made this a bit challenging along with

the fact that left hand threads in a blind hole didn't seem easy to do.

This tool just threads on by hand and when the draw bar is loosened, it pushes down on the taper

and dislodges it. I thought it worth my whiile to make this so one doesn't have to beat on the draw bar

and bearings.

Here's a couple photos:

View media item 96429View media item 96430

My guess is that you use this tool and remove it when done using it...

Last edited: