E

ecdez

Forum Guest

Register Today

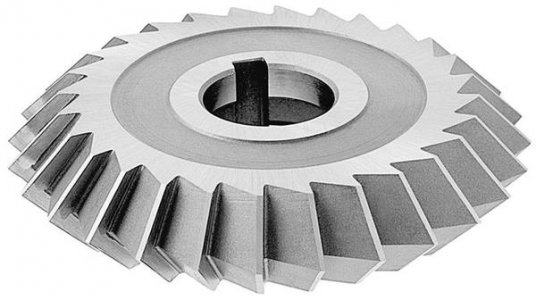

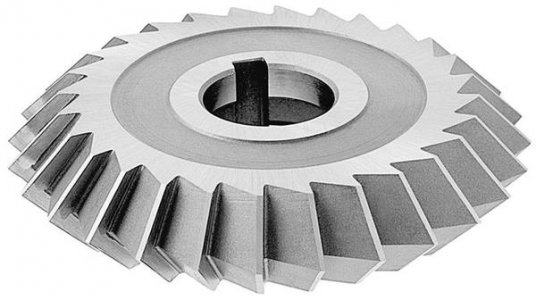

So I have one of these that's gotten a little dull. I understand the sharpening process but I do not have a fixture for it and only a surface grinder to work with. Is it even possible with what I have (and can make for a fixture) or is all lost and I should cough up the money for a new one. Getting it professionally sharpened could be an option as long as it's not the same price as a new one but I'd prefer to do it myself if I can. That's kind of the hobbyist slogan right?