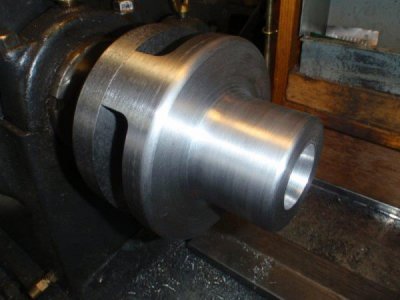

I didn't spring for the $$$ collet closer when I bought my lathe, in part because it looked like it would be a bear to set up and tear down.

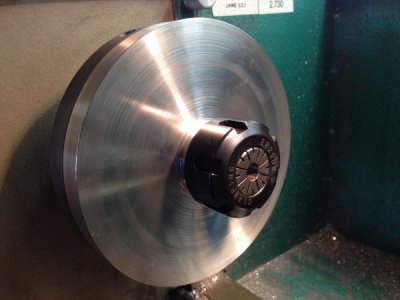

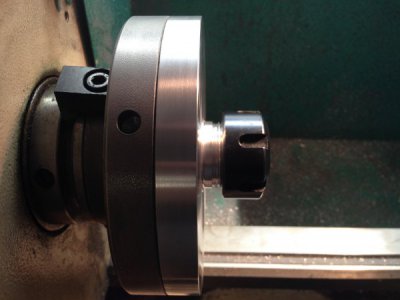

As far as collet options go, any thoughts on the relative merits of the 5C cam mounting chucks such as the

Grizzly T10459, vs the ER40 setups like the MT5ER40S23 from ZLiveCenter? I imagine another option would be to turn a MT5 to 5C adaptar sleeve and make a draw tube to hold the collet in place.

As far as collet options go, any thoughts on the relative merits of the 5C cam mounting chucks such as the

Grizzly T10459, vs the ER40 setups like the MT5ER40S23 from ZLiveCenter? I imagine another option would be to turn a MT5 to 5C adaptar sleeve and make a draw tube to hold the collet in place.