- Joined

- Sep 11, 2015

- Messages

- 293

Hey y'all it's been a long time since I posted. Haven't been involved with anything to do with machining much recently due to life getting in the way.

Well the time has come from me to get my feet back in the water. I'm wanting to build a ball/radius attachment for my Grizzly G4003G lathe. My problem is fining a simple way to make one that doesn't require a lathe. I have done some research and most of the ones I looked at seemed to need a mill at one point.

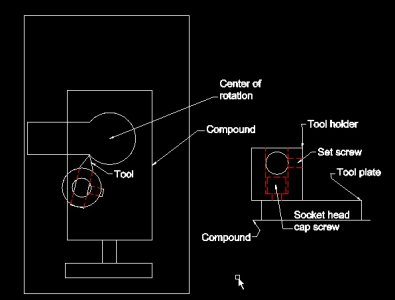

I do not have a mill and have no access to one at the moment. Does anybody have any ideas for me to make a simple one? I'm thinking something like the one in this ebay picture I attached. Any better suggestions?

Well the time has come from me to get my feet back in the water. I'm wanting to build a ball/radius attachment for my Grizzly G4003G lathe. My problem is fining a simple way to make one that doesn't require a lathe. I have done some research and most of the ones I looked at seemed to need a mill at one point.

I do not have a mill and have no access to one at the moment. Does anybody have any ideas for me to make a simple one? I'm thinking something like the one in this ebay picture I attached. Any better suggestions?