Hello All,

New to the forum and to craftsman atlas lathes. I was recently given a model 101.07381 12" by my father, serial # 4583s. It is in fair condition, operating at the moment. I was trying to date the lathe and had a few questions.

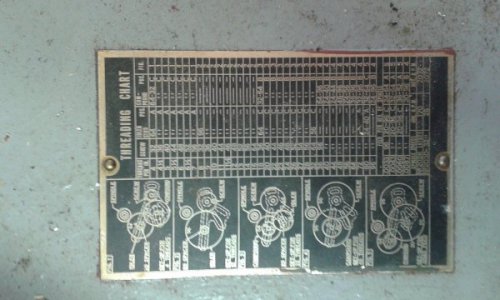

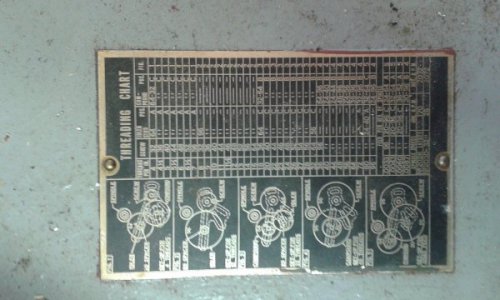

First question. the change gear cover case has a threading chart as almost all do, but this one is showing diagrams for 96 tooth gears. The diagram also show instead of them going through a stud gear to the 2 fwd rev gears that it would be connected straight to the spindle.? the MOLO I have for craftsman is the 21st edition and shows the fwd rev gear selector. The lathe does have a fwd rev lever and does work, but I am missing both the 96 tooth gears.

If I were to follow the threading chart in the manual I would not need them for the threads I would like to cut, would this still work as designed, and am I missing something when looking at the original threading chart on the machine?

New to the forum and to craftsman atlas lathes. I was recently given a model 101.07381 12" by my father, serial # 4583s. It is in fair condition, operating at the moment. I was trying to date the lathe and had a few questions.

First question. the change gear cover case has a threading chart as almost all do, but this one is showing diagrams for 96 tooth gears. The diagram also show instead of them going through a stud gear to the 2 fwd rev gears that it would be connected straight to the spindle.? the MOLO I have for craftsman is the 21st edition and shows the fwd rev gear selector. The lathe does have a fwd rev lever and does work, but I am missing both the 96 tooth gears.

If I were to follow the threading chart in the manual I would not need them for the threads I would like to cut, would this still work as designed, and am I missing something when looking at the original threading chart on the machine?