- Joined

- Jul 26, 2011

- Messages

- 4,142

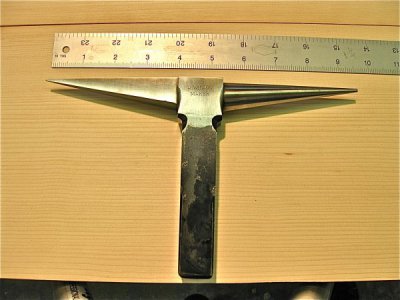

What technical aspects? You put black powder in the cavity under the anvil,supply a cannon fuse,sit it atop another anvil and you're ready to go! You might have to put tape over the cavity in the top anvil to keep the powder from falling out while you sit it on the other anvil.

You might have to put tape over the cavity in the top anvil to keep the powder from falling out while you sit it on the other anvil.

I wonder if you really can expect the bottom anvil to remain level and true when the blast goes off ?

I wonder if you really can expect the bottom anvil to remain level and true when the blast goes off ?