-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Outboard Spider Or Steady Rest For Barrel Work?

- Thread starter calstar

- Start date

- Joined

- Jul 31, 2016

- Messages

- 8

Brian

I use headstock,with ,back spider for barrel work.BUT

I use half moon small split/cut pieces of SS rod for chuck, to make the barrel pivot easier.

Some guys use tabs of aluminum. Copper wires on chuck /4 jaw.

I just found out some smiths call it a Jimbull/or something like that.

on the cat/spider 4 screws but I use it to aid indicating in the chamber leade area/, not the muzzle end of barrel.

depends on your set up.i have used indicating rods/ Gordy rods/ indicator, they all work .

lot of smiths use fancy tools which is Ok .main thing to barrel as straight as possible,

hope this helps.

Noahtenbears

I use headstock,with ,back spider for barrel work.BUT

I use half moon small split/cut pieces of SS rod for chuck, to make the barrel pivot easier.

Some guys use tabs of aluminum. Copper wires on chuck /4 jaw.

I just found out some smiths call it a Jimbull/or something like that.

on the cat/spider 4 screws but I use it to aid indicating in the chamber leade area/, not the muzzle end of barrel.

depends on your set up.i have used indicating rods/ Gordy rods/ indicator, they all work .

lot of smiths use fancy tools which is Ok .main thing to barrel as straight as possible,

hope this helps.

Noahtenbears

- Joined

- Jul 31, 2016

- Messages

- 8

To BamBan.

Nice ,But I have a couple of questions and comments.

I have made 4 Jigs for doing actions , but what has always bugged me ,most smiths use brass bolts, and looking

at their products,i was puzzled.

How do they get a flat surface to pivot on a flat surface, sort of like a sea/saw.

flat surface board middle and on each end,and a flat bolt/ brass bolt.

You Sir went to round ball bearings /which I had to do the same, and works super easy.

Now the way I see it an action can bend /like a savage.

you have to be gentle with em.

Now on the pics of your cat you have what looks aluminum spacers/ half moon blocks/ with tape.

Do you use your cat to center/indicate your muzzle or use your cat bolts to aid in indicating your area where your

cartridge/ bullet chamber.

Please explain , at 63 I have learned there is more than one way to skin a cat.

noahtenbears

Nice ,But I have a couple of questions and comments.

I have made 4 Jigs for doing actions , but what has always bugged me ,most smiths use brass bolts, and looking

at their products,i was puzzled.

How do they get a flat surface to pivot on a flat surface, sort of like a sea/saw.

flat surface board middle and on each end,and a flat bolt/ brass bolt.

You Sir went to round ball bearings /which I had to do the same, and works super easy.

Now the way I see it an action can bend /like a savage.

you have to be gentle with em.

Now on the pics of your cat you have what looks aluminum spacers/ half moon blocks/ with tape.

Do you use your cat to center/indicate your muzzle or use your cat bolts to aid in indicating your area where your

cartridge/ bullet chamber.

Please explain , at 63 I have learned there is more than one way to skin a cat.

noahtenbears

- Joined

- Jul 31, 2016

- Messages

- 8

To BAMBAN

Sorry I got it bass/ackwards.

got to get some windex for my speckers.

your chamber area is taped and blocked.

and your muzzle end is blocked.

noahtenbears

Sorry I got it bass/ackwards.

got to get some windex for my speckers.

your chamber area is taped and blocked.

and your muzzle end is blocked.

noahtenbears

- Joined

- Jul 13, 2014

- Messages

- 1,051

Now on the pics of your cat you have what looks aluminum spacers/ half moon blocks/ with tape.

Do you use your cat to center/indicate your muzzle or use your cat bolts to aid in indicating your area where your

cartridge/ bullet chamber.

Please explain , at 63 I have learned there is more than one way to skin a cat.

noahtenbears

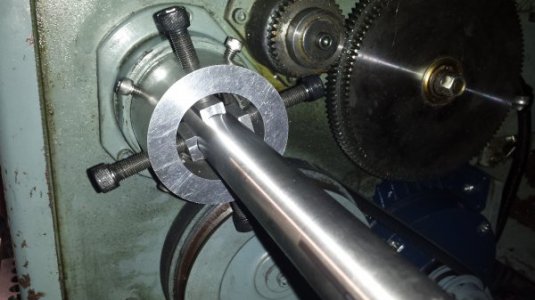

The tape on the muzzle is just to protect the scroll and polished finish I put on the barrel.

As far as indicating, this is what I do "use your cat bolts to aid in indicating your area where your

cartridge/ bullet chamber."

My long barrel threading and chambering work is done through the headstock, using a range rod to indicate the bore.

The key to getting a stress free set up is to use barely enough pressure on the spider screws when dialing in.

Then tighten slowly and evenly so that the barrel won't slip while turning.

No matter what approach is used to hold the barrel it has to slip easily when dialing but after be held tight enough for turning.

It is too easy to stress a barrel without noticing it when dialing in. This is what takes practice.

The advantages are that it works for me and my equipment but plenty of good barrel work is done by other methods

The key to getting a stress free set up is to use barely enough pressure on the spider screws when dialing in.

Then tighten slowly and evenly so that the barrel won't slip while turning.

No matter what approach is used to hold the barrel it has to slip easily when dialing but after be held tight enough for turning.

It is too easy to stress a barrel without noticing it when dialing in. This is what takes practice.

The advantages are that it works for me and my equipment but plenty of good barrel work is done by other methods

Last edited:

To BamBan.

How do they get a flat surface to pivot on a flat surface, sort of like a sea/saw.

flat surface board middle and on each end,and a flat bolt/ brass bolt.

Please explain , at 63 I have learned there is more than one way to skin a cat.

noahtenbears

Although your question was addressed to Bamban may I offer some comments on this question.

I use a relatively softer metal (like copper, brass or aluminum) between the screws and barrel to avoid marring the barrel but still have a solid hold. The adjustment involved in dialing a barrel does create some rocking of the flat surfaces you refer to. However the amount of sea/saw is so minute that the soft material under the spider screw will 'give' and keep the contact patch relatively flat.

It leads to the question of what size of spider screw would be optimal.

- Joined

- Apr 8, 2013

- Messages

- 1,976

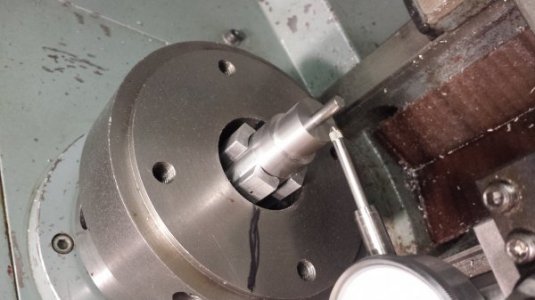

I use this in the 4 jaw on the chamber end to prevent torqueing the barrel. The spider is on the other end. I only use a steady for barrel contouring. The first thing I do with a new blank is put it on centers to true the OD with the bore. Then I don't need to do any hocus pocus with the bore, just indicate on the OD. I don't have rods or bushings.

- Joined

- Mar 15, 2016

- Messages

- 64

I use the outboard spider but as mentioned earlier I use it to align the barrel in the chuck whether I'm working on the chamber or crowning the muzzle. I use the copper wire in the chuck and brass tipped screws in the spider. I've only done one so far but it seems to have worked. Used the Gordy type indicator rod and it worked great. First 3 shot group measured .117 ctc. First 5 measured .296 ctc. I think it worked.