Hi TommyD, Toolroom, thank you,

The blank was not hardened at the video. Just in the state W1 come from the supplier.

This did not work very well. My CNC spindle is too fast for steel (8000 RPM min) and the CNC had a problem at the time; the Z axis was "wandering". So the sides of the cutter ended up not exactly symmetrical.

Now I use a different method to cut the profile.

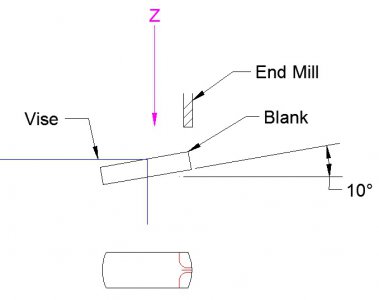

The blank is mounted on the CNC vise inclined to 10 degrees upward to create the relief angle.

I've used a 1/8" 4-flute end mill, shallow cuts and slow feed rate.

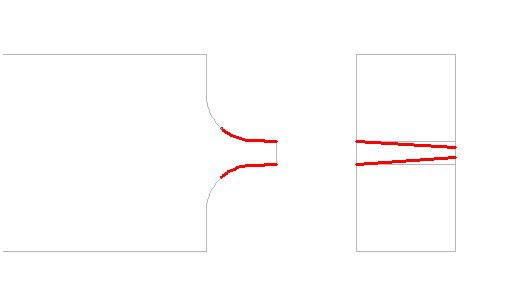

The relief is ok in most of the profile, but the faces marked in RED here are "improved" by hand with files and a rotary tool grinder.

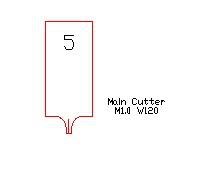

The cutters are made of W1 tool steel and water-hardened afterwards.

Wagner