- Joined

- Feb 12, 2016

- Messages

- 11

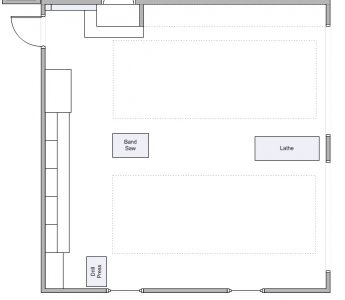

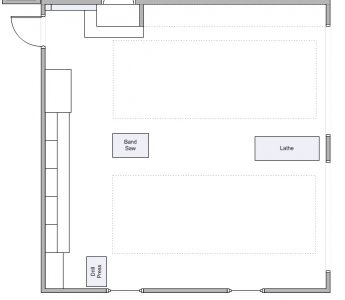

I'm slowly putting together a work shop. Recently I picked up a lathe, picture attached.

You will notice it is temporarily on loading castors as I try to decide where to put it. I'm just getting started in this hobby. This forum appears to have a wealth of good information on how to get started. Any advice on where I should put this fairly permanent tool? My shop is a 24'x24' double car garage attached to the house, pic attached as well.

Many thanks!

You will notice it is temporarily on loading castors as I try to decide where to put it. I'm just getting started in this hobby. This forum appears to have a wealth of good information on how to get started. Any advice on where I should put this fairly permanent tool? My shop is a 24'x24' double car garage attached to the house, pic attached as well.

Many thanks!