- Joined

- Nov 10, 2013

- Messages

- 837

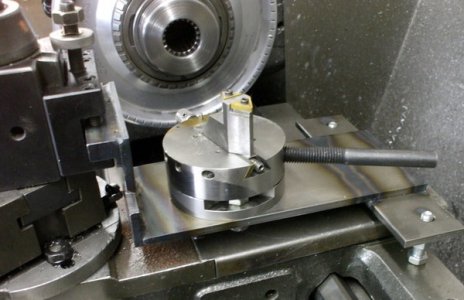

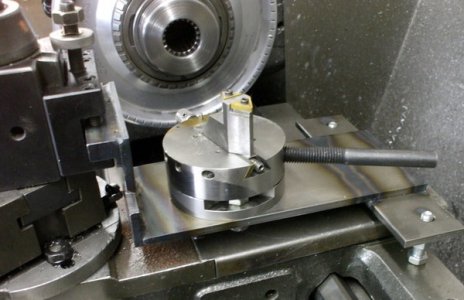

I already have a home made ball turner but hesitate to use it much because it requires removing my compound to mount directly to the lathe saddle. Well last week I underestimated the size of knob I needed for a rifle and had to remove the turner and reinstall the compound and start over (grumbling the whole time).

Coincidentally, GarageGuy posted his quick change tool post ball turner and it struck me that it made more sense to have one that could be removed and installed easily. I let the idea roll around in my head for a few days thinking about a design that had all the features of my original one yet would work with the QC toolpost. Yesterday I got the old turner out and just set it on top the saddle looking for inspiration when the idea struck to just make an adapter for the turner I already had.

I pulled some salvaged 4" x 1/4" plate out from under a bench and made it today before I left for work.

I only had a few minutes after it was all done to test it out, but it should make great bolt knobs!

Coincidentally, GarageGuy posted his quick change tool post ball turner and it struck me that it made more sense to have one that could be removed and installed easily. I let the idea roll around in my head for a few days thinking about a design that had all the features of my original one yet would work with the QC toolpost. Yesterday I got the old turner out and just set it on top the saddle looking for inspiration when the idea struck to just make an adapter for the turner I already had.

I pulled some salvaged 4" x 1/4" plate out from under a bench and made it today before I left for work.

I only had a few minutes after it was all done to test it out, but it should make great bolt knobs!