- Joined

- Jun 17, 2011

- Messages

- 2,062

I mentioned a few months ago that, when I was reconditioning my shop equipment after my house fire, the dolly under my Hercus (Australian SB9) lathe gave way and the lathe fell forward, bending the X-axis and crossfeed cranks and breaking the end off the crossfeed screw.

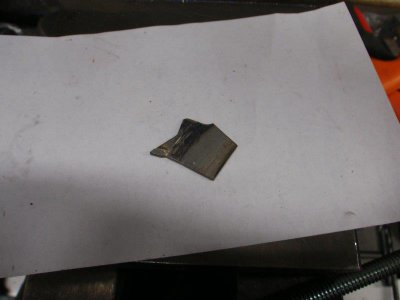

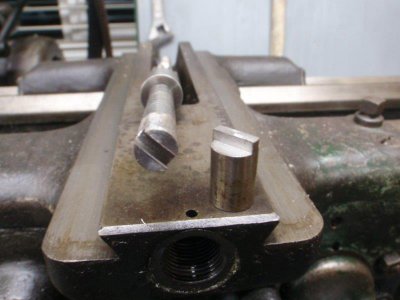

I finally have the shop far enough along that I felt it was time to at least start on repairing the lathe. I managed to straighten the X-axis crank well enough some time ago. It took a lot of brute strength and ignorance to take the crossfeed apart. Several parts had been bent to various degrees and were binding as the shaft was turned. The sundry components are seen here, including the end of the shaft that had been broken off.

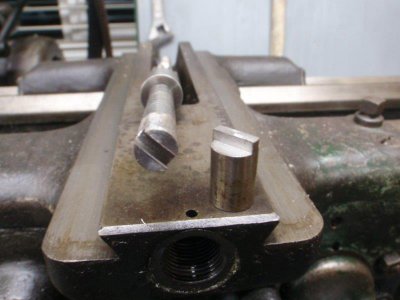

After straightening the shaft in two areas, and the screw-in shaft bearing, I milled a slot across the end of the shaft with a Woodruff key cutter about 1/3 as wide as the shaft diameter. I milled a matching tenon in a piece of 1/2" CRS. A slip fit seemed like a good idea to allow room for silver solder to wick in.

After applying flux to the parts, I cut three short pieces of silver solder and placed them on the horizontal surfaces of the joint and heated the whole area with the oxy-acetylene torch, starting with the larger diameter piece, until the solder was thoroughly melted. I then allowed it to cool naturally.

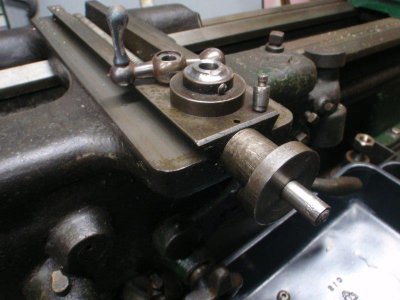

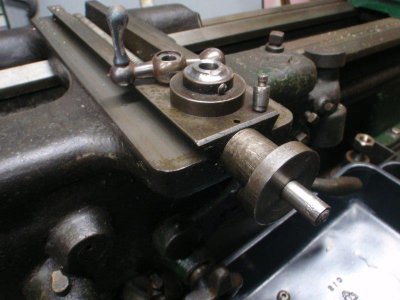

The shaft was then mounted in my 5C collet chuck and centre drilled with a very small drill. After remounting it, using the bearing centre in the tailstock, I turned the added piece to match the original shaft end.

Next, the end section was turned down to a smaller diameter to fit into the crank. Then the tip was turned down to allow threading to #12 - 24, using the die-holder guided by the tailstock.

The whole arrangement fit together quite well. The only operation still required is to cut a 1/16" wide Woodruff key slot in the part where the crank body fits. That will require making a cutter, since I don't have one that small and they are dismally expensive. I guess that means I have to get the heat treating oven wired up and learn how to use it.

I finally have the shop far enough along that I felt it was time to at least start on repairing the lathe. I managed to straighten the X-axis crank well enough some time ago. It took a lot of brute strength and ignorance to take the crossfeed apart. Several parts had been bent to various degrees and were binding as the shaft was turned. The sundry components are seen here, including the end of the shaft that had been broken off.

After straightening the shaft in two areas, and the screw-in shaft bearing, I milled a slot across the end of the shaft with a Woodruff key cutter about 1/3 as wide as the shaft diameter. I milled a matching tenon in a piece of 1/2" CRS. A slip fit seemed like a good idea to allow room for silver solder to wick in.

After applying flux to the parts, I cut three short pieces of silver solder and placed them on the horizontal surfaces of the joint and heated the whole area with the oxy-acetylene torch, starting with the larger diameter piece, until the solder was thoroughly melted. I then allowed it to cool naturally.

The shaft was then mounted in my 5C collet chuck and centre drilled with a very small drill. After remounting it, using the bearing centre in the tailstock, I turned the added piece to match the original shaft end.

Next, the end section was turned down to a smaller diameter to fit into the crank. Then the tip was turned down to allow threading to #12 - 24, using the die-holder guided by the tailstock.

The whole arrangement fit together quite well. The only operation still required is to cut a 1/16" wide Woodruff key slot in the part where the crank body fits. That will require making a cutter, since I don't have one that small and they are dismally expensive. I guess that means I have to get the heat treating oven wired up and learn how to use it.