- Joined

- May 23, 2014

- Messages

- 100

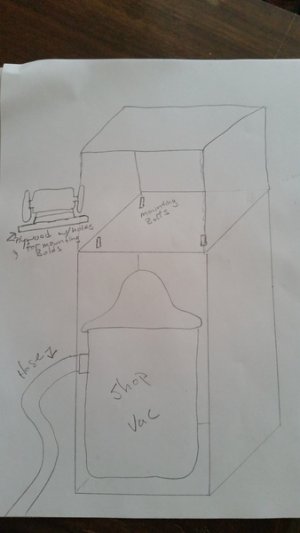

Hello like minded tool people, I need some input. In my new home shop dust is an issue and it has limited counter space. I plan on killing these two birds with a pile of 2x4's. Before doing so I'd like to here some input from others who likely have more experience than me. This is my plan. I have 3 bench grinders all with different wheels, a 12" disk sander, 6" buffer and a powder coating machine that all have two things in common. They make lots of dust and I have no place for them. I'd like to build a table that's 24"×24". Under the table will be a closed off compartment for my shop vac. It will be sound insulated . There's several good YouTube videos about sound proofing the shop vac and it makes a big difference. The table top will have a lid or box on it. Something big enough to house the tools mentioned above one at a time. I need to pipe in the shop vac in an efficient manner to collect the dust made by these machines.

Each tool will be mounted on a piece of plywood with holes in all 4 corners to match the 4 bolt studs sticking up from the table top. This way I can quickly change out the tools and secure them with wing nuts.

I'd also like to use this for small powder coating. This shop vac will be to strong though. I'll tackle this part later.

Now to the point of this long post. Will it work to collect dust efficiently? What's the best way to run the vac line? I can make a dust table with lots of holes or just make one port on the back wall. It's a 16 gallon ridgid so it has good power. Any ideas on the best way to implement this plan? Here's a sketch for you to laugh at and ponder

Each tool will be mounted on a piece of plywood with holes in all 4 corners to match the 4 bolt studs sticking up from the table top. This way I can quickly change out the tools and secure them with wing nuts.

I'd also like to use this for small powder coating. This shop vac will be to strong though. I'll tackle this part later.

Now to the point of this long post. Will it work to collect dust efficiently? What's the best way to run the vac line? I can make a dust table with lots of holes or just make one port on the back wall. It's a 16 gallon ridgid so it has good power. Any ideas on the best way to implement this plan? Here's a sketch for you to laugh at and ponder