- Joined

- Feb 24, 2015

- Messages

- 1,382

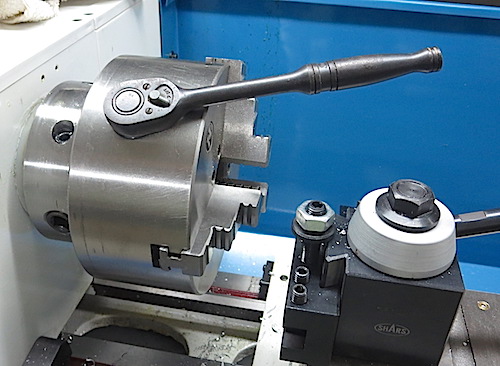

The jaws on my chuck are pretty tight. Turning them in and out can be a chore.

I started looking around the shop for something to make a crank handle. I measured the chuck wrench and discovered it is 3/8"

I've got 3/8 crank handles all over the shop, including electric powered ones. How convenient. I don't have to make anything.

I think the ratchet wrench is a much better chuck wrench than the t-handle wrench it came with.

The speed wrench is great for opening and closing the jaws to the extremes.

I started looking around the shop for something to make a crank handle. I measured the chuck wrench and discovered it is 3/8"

I've got 3/8 crank handles all over the shop, including electric powered ones. How convenient. I don't have to make anything.

I think the ratchet wrench is a much better chuck wrench than the t-handle wrench it came with.

The speed wrench is great for opening and closing the jaws to the extremes.

Last edited: