-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Vise For An Atlas Mfc Horizontal Mill?

- Thread starter spongerich

- Start date

I have an original vise for sale, but you will not like the price.You could look for a Palmgren low profile milling vise.

- Joined

- Mar 3, 2013

- Messages

- 1,448

- Joined

- Apr 25, 2014

- Messages

- 6

- Joined

- Nov 23, 2014

- Messages

- 2,606

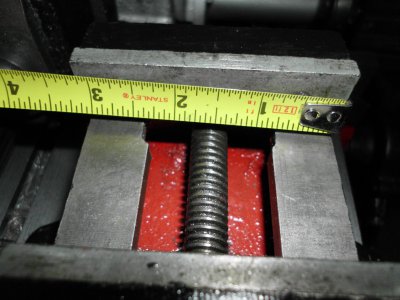

I bought a 3" swivel vise from eBay seller "topqu0987" for around $75 delivered. The vise has a coolant-containing ridge around the base, I band sawed off the overhang on the fixed jaw side and cleaned it up on my vertical mill. Set the vise back on the swivel base and measured the distance from the edge of the swivel to the back of the fixed jaw side of the vise. I wanted the swivel base edge to be flush with the fixed jaw side of the vise. Set the vise w/base back on the mill table with the table at its limit of travel toward the column. Slid the vise to within about 1/16" from the column and measured (roughly) the distance between the center of the table slot and the open-ended slots in the base which is the offset for the locating blocks and new open-ended slots on the swivel base.

Set the base upside down on my vertical mill, indicated in the existing slot on the bottom of the base. Milled a slot along the base for the new location of the locating blocks & open-ended bolt slots. Made blocks to fit the table and the swivel base slot.

The vise opens up to just over 3", jaws are just over 3" wide. I have about 3 1/4" from the bottom of the vise surface to the center of the arbor. The photos of the base with orange circles show areas that were removed to clear the column.

The vise is pretty true; indicates flat to my table within 0.001" across the top of the fixed jaw and the surface. I'd prefer a little more vertical room between the vise and arbor, but that's the compromise with a small mill.

Set the base upside down on my vertical mill, indicated in the existing slot on the bottom of the base. Milled a slot along the base for the new location of the locating blocks & open-ended bolt slots. Made blocks to fit the table and the swivel base slot.

The vise opens up to just over 3", jaws are just over 3" wide. I have about 3 1/4" from the bottom of the vise surface to the center of the arbor. The photos of the base with orange circles show areas that were removed to clear the column.

The vise is pretty true; indicates flat to my table within 0.001" across the top of the fixed jaw and the surface. I'd prefer a little more vertical room between the vise and arbor, but that's the compromise with a small mill.

- Joined

- Mar 22, 2014

- Messages

- 847

Would this vise be suitable?

http://www.shars.com/products/toolh...ision-milling-machine-vise-with-swivel-base-1

http://www.shars.com/products/toolh...ision-milling-machine-vise-with-swivel-base-1

- Joined

- Mar 22, 2014

- Messages

- 847

OK. After doing some research and studying BGHansen's photos (Thanks BGHansen), I can answer my own question. The small "Shars" vise is sold under a variety of familiar brand names, and it does not fit the Atlas mill very well.

- Joined

- Oct 20, 2014

- Messages

- 495

I have been eyeballing a 4" screwless vice for my Atlas MFC. Mostly because it can be laid on it's side and clamped down, so it presents the work more like a conventional vertical mill. Right now I use a regular mill vice, without the swivel base installed, and it's tedious at best. Mostly I've found that I use my clamping kit and blocks to clamp directly to the table. I really wish I could make a tooling plate for it, but the thickest metal I have on hand is only 3/8" plate.