- Joined

- Jul 27, 2013

- Messages

- 295

Good News, Mike!

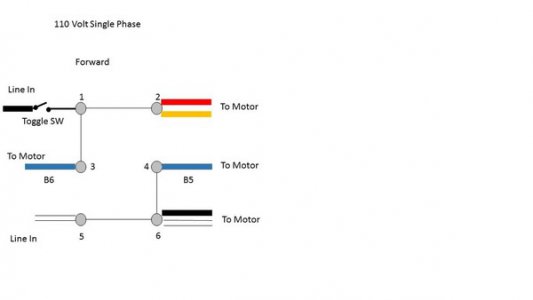

The toggle switch is probably too convenient. It is in a great spot to turn it off in a pinch without having to reach over the lathe or under something where you might miss, but also to bump it by accident, and it can be in the way for carriage stops and such. I will probably wire it to work because that's how it came, and that's how I am, but I will take moving it under advisement right from the start. I have in my mind that I don't think I care for the later guard frame mounting of the drum switch. We shall see.

Now you will be loving the back gear shaft slot mod! I got mine adjusted really well and the back gears make little more noise than without them engaged. Chips are coming very soon!!

The toggle switch is probably too convenient. It is in a great spot to turn it off in a pinch without having to reach over the lathe or under something where you might miss, but also to bump it by accident, and it can be in the way for carriage stops and such. I will probably wire it to work because that's how it came, and that's how I am, but I will take moving it under advisement right from the start. I have in my mind that I don't think I care for the later guard frame mounting of the drum switch. We shall see.

Now you will be loving the back gear shaft slot mod! I got mine adjusted really well and the back gears make little more noise than without them engaged. Chips are coming very soon!!