- Joined

- Feb 2, 2013

- Messages

- 3,620

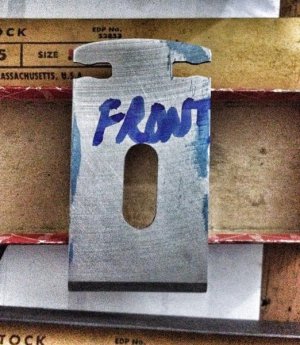

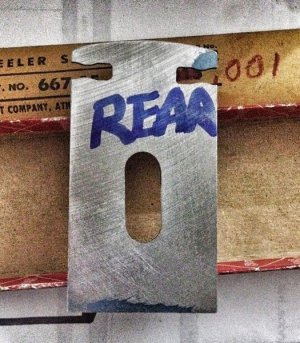

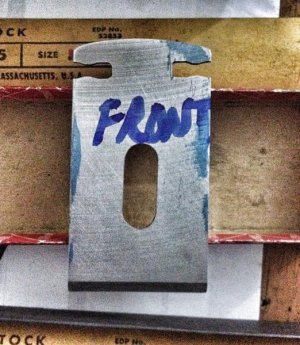

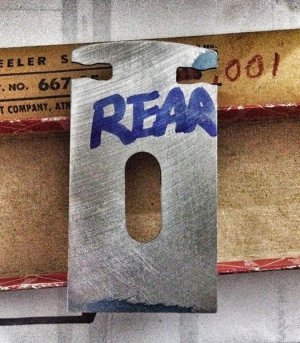

I started working the blade of the plane, heres how the blade blued up after a few lapping cycles.

the lapping was achieved by laying 400 grit wet/dry sandpaper on the surface plate.

by adding some glass cleaner as the wet agent and a coarse grain foam sanding block as the makeshift work holder.

the coarse foam block almost adheres to the blade and makes the lapping a lot safer than trying to push the blade by hand.

i surmise that it would also apply a more even pressure over the surface of the blade as well.

pictures of the rubbings

it's gonna need some work!

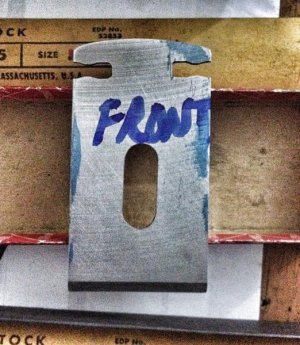

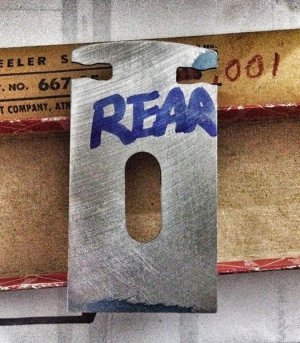

the lapping was achieved by laying 400 grit wet/dry sandpaper on the surface plate.

by adding some glass cleaner as the wet agent and a coarse grain foam sanding block as the makeshift work holder.

the coarse foam block almost adheres to the blade and makes the lapping a lot safer than trying to push the blade by hand.

i surmise that it would also apply a more even pressure over the surface of the blade as well.

pictures of the rubbings

it's gonna need some work!