- Joined

- Nov 5, 2010

- Messages

- 871

A few years ago I was invited by a friend to his father-in-law's shop, where he was liquidating "all the junk" in case I was interested in it. The only thing I saw was a cute little horizontal mill. But another guy had already called dibs on it.

But I kept in touch, until recently I heard the guy was ready to sell it, having done nothing with it.

So long story short, here's what I ended up with:

It was made in 1943. It needs a motor and some sort of mount.

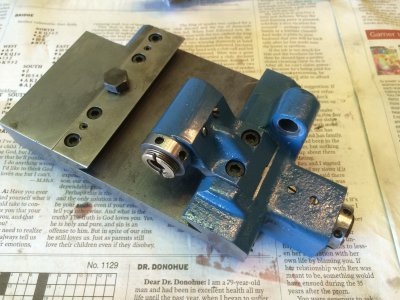

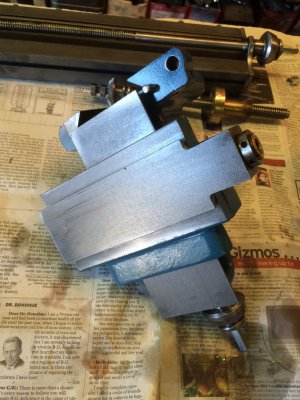

It came with the tooling you see here. The only major item missing is the dividing head, though it has the base, tailstock, drawbar and a couple of mounting centers for it.

Fortunately it came with the original vise, collets, drawbar, and two arbors.

I have spent the last week cleaning and stripping everything. Updates to follow

But I kept in touch, until recently I heard the guy was ready to sell it, having done nothing with it.

So long story short, here's what I ended up with:

It was made in 1943. It needs a motor and some sort of mount.

It came with the tooling you see here. The only major item missing is the dividing head, though it has the base, tailstock, drawbar and a couple of mounting centers for it.

Fortunately it came with the original vise, collets, drawbar, and two arbors.

I have spent the last week cleaning and stripping everything. Updates to follow

Last edited: