Are there any advantages to a larger insert tool holder other than more rigidity?

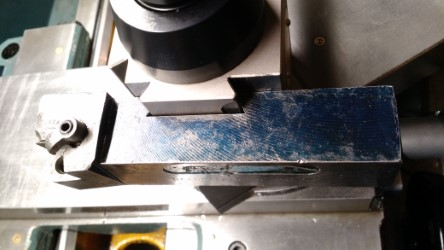

I have an oversize tool holder that an accept 1" shank tools. I have a BXA post and looks like alignment (center of work) will not be a problem. Was looking at a holder on Ebay that accepts the TP.. 322 types inserts.

I'm trying to grind my own HSS tools but thought it might be worthwhile to have one of these.

I have an oversize tool holder that an accept 1" shank tools. I have a BXA post and looks like alignment (center of work) will not be a problem. Was looking at a holder on Ebay that accepts the TP.. 322 types inserts.

I'm trying to grind my own HSS tools but thought it might be worthwhile to have one of these.