- Joined

- Feb 8, 2014

- Messages

- 11,144

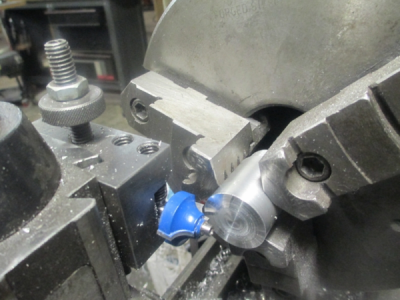

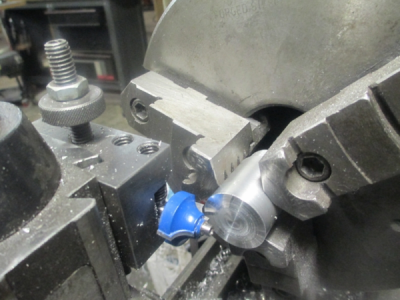

Gunrunner you need to order a set of these for the Z axis hand crank. Bill did you just spit coffee on your monitor? :rofl:

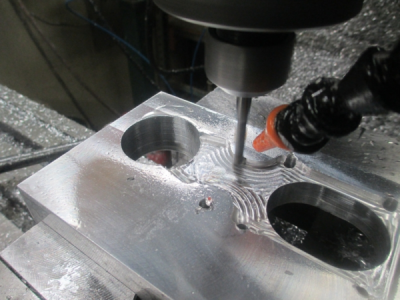

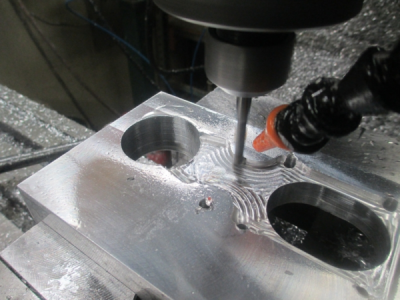

View attachment 253356

View attachment 253356

Last edited: