Hi all,

Recently acquired a 1950 Victoria U2 mill with a 2 speed (2800/1450) motor rated at 6/4hp. Some pics:

I am arranging for the mains supply to my house and workshop to be upgraded to 3ph - will take a few weeks. In the meantime, I'd like to understand my options for fitting a 3ph VFD to the mill.

I confess to having very little knowledge of these things, although I did manage to upgrade my drill press with a VFD that runs a 1hp 3ph motor at 230V. This was achieved with a new motor, preconfigured VFD and a remote control supplied (complete with idiot sheets) by a local electric motor specialist.

However, the Victoria mill is a different challenge as I want to retain the original motor.

What I would like to achieve is variable speed control and, if possible, electric braking of the motor when an emergency stop button is pressed.

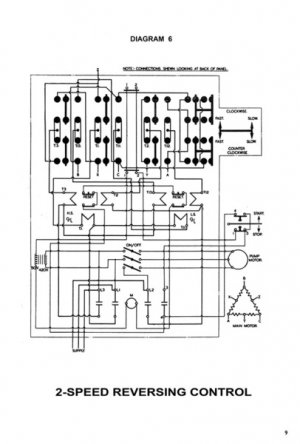

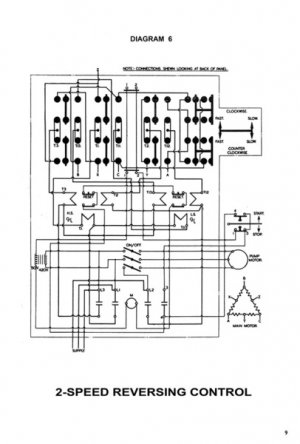

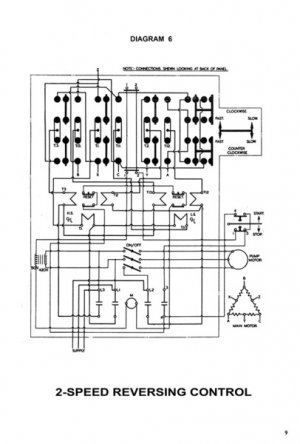

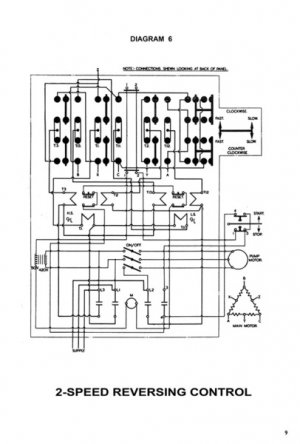

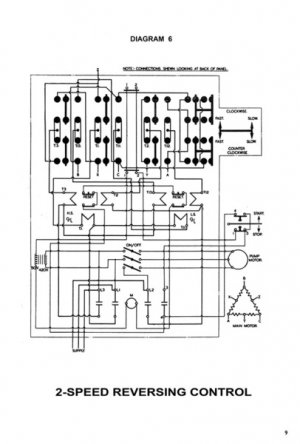

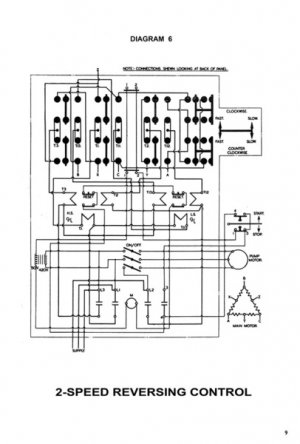

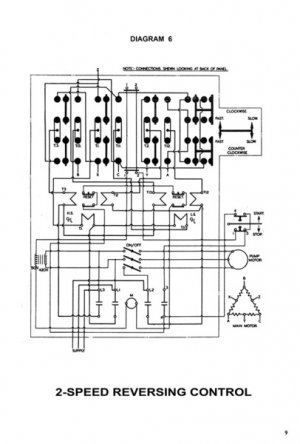

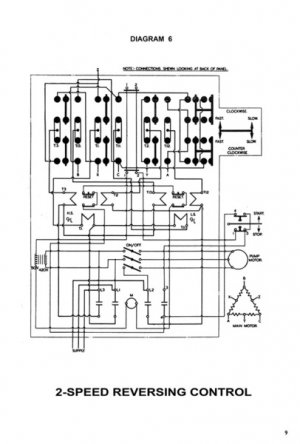

I have attached a copy of the wiring diagram in the hope that someone can offer me some advice on how to go about this. Cheers.

Recently acquired a 1950 Victoria U2 mill with a 2 speed (2800/1450) motor rated at 6/4hp. Some pics:

I am arranging for the mains supply to my house and workshop to be upgraded to 3ph - will take a few weeks. In the meantime, I'd like to understand my options for fitting a 3ph VFD to the mill.

I confess to having very little knowledge of these things, although I did manage to upgrade my drill press with a VFD that runs a 1hp 3ph motor at 230V. This was achieved with a new motor, preconfigured VFD and a remote control supplied (complete with idiot sheets) by a local electric motor specialist.

However, the Victoria mill is a different challenge as I want to retain the original motor.

What I would like to achieve is variable speed control and, if possible, electric braking of the motor when an emergency stop button is pressed.

I have attached a copy of the wiring diagram in the hope that someone can offer me some advice on how to go about this. Cheers.