- Joined

- Aug 15, 2013

- Messages

- 2,116

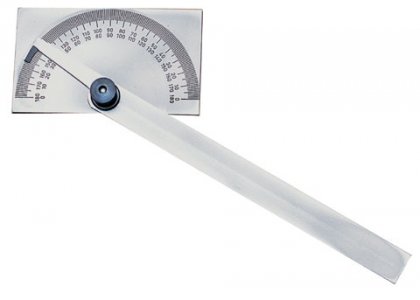

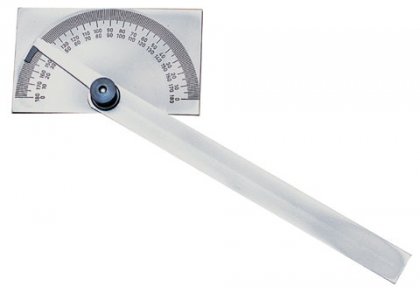

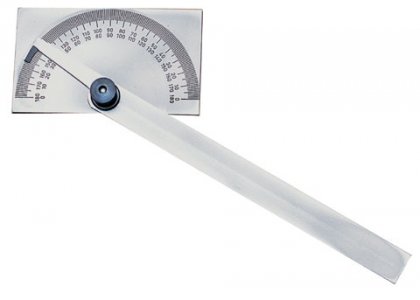

I think T Bredehoft and pdentrem nailed it. If you're using the built in protractor to set the compound angle, those usually measure degrees off of parallel with the ways. What you want is 29-30 degrees off the direction of cross slide travel, or 60-61 degrees off parallel to the ways. You may need one of these to set the angle with.

Tom

Tom